After the Fall is a two-act, autobiographical play by Arthur Miller that delves into his marriage with Marilyn Monroe and other notable aspects of his public and private life. It was produced on stage and in film for television. “Fall” represents a person’s tumble through consciousness into choice.

In theaters, studios, and other entertainment or recreational venues—as well as within the supporting hospitality industry—a fall can be a person’s tumble that results in an injury. Fortunately, business owners, building managers, and other responsible parties can consciously choose to provide safe public access and fall protection for their staff and patrons.

Introducing access.

Ensuring accessibility for all individuals—including those in a wheelchair —is critical to safety and compliance with the landmark Americans with Disabilities Act (ADA). Highly visible public places like hotels, restaurants, and sports facilities are easily scrutinized.

ADA-compliant wheelchair ramps are essential for providing safe and easy access to various areas within these establishments. Ramps must be designed with the correct slope, handrails, and surface materials to prevent slips and falls. Properly installed and maintained wheelchair ramps comply with legal requirements and demonstrate a commitment to inclusivity and customer care.

A modular wheelchair access ramp is an ideal way to retrofit a building without costly redesign and construction. Easy to customize for various entrances and pathways, the system features lightweight aluminum floor frames, anti-slip fiberglass mesh, adjustable, powder-coated steel balustrades, and “warm-to-touch” PVC handrail tubes.

Straight-run ramps can be installed using only a bolt driver in a few hours. No expensive welding or specialized labor is required. Even complicated “switchback” designs can be built in less than a day. The lightweight, high-strength aluminum and durable, powder-coated steel components are corrosion-resistant and withstand extreme weather conditions and heavy use. All-weather treads prevent ice and snow accumulation.

Modular ramps meet or exceed ADA standards for slope (1:12), minimum width (36 inches), rest intervals for every 30 feet of vertical rise, landings, handrails, and edge protection along the sides of the ramp. They not only provide compliant wheelchair access but are also indispensable for people using a walker, cane, crutches, or scooter—even pushing a stroller. Accessibility means inclusiveness for all.

Set the stage for platforms.

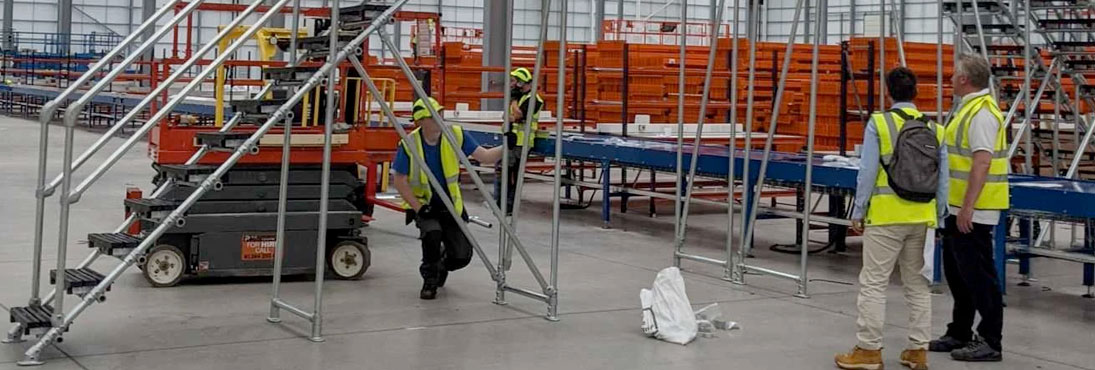

Elevated work platforms provide stable and secure access for stage set-up, performances, inventory storage, machinery maintenance, and other activities. Their modular construction features aluminum or galvanized steel frames to support anti-slip treads for steps and platform decks. Pipe-fitted guardrails provide necessary and compliant work-at-height fall protection. Self-closing safety gates can be added to prevent workers from falling back through an opening or down the steps.

Work platforms provide outstanding versatility to fit the venue and tasks:

- Fixed Access Work Platforms are ideal for permanent installations and frequent work.

- Mobile Work Platforms are fitted with heavy-duty locking casters, allowing station-to-station portability without the safety risks and productivity hindrances of ladders.

- Adjustable Work Platforms are fabricated workstations raised and lowered to access different areas and heights.

- Custom Work Platforms are designed and built for specialized or complex tasks and can include electrical, air, and water connections.

An added step for safety.

“Crossovers” allow safe passage over obstacles such as pipes or cables and are essential in areas with high foot traffic or where maintenance work is regularly performed. By “crossing over” obstacles, these fall protection devices prevent trips and falls, ensuring people can move safely through the facility.

Crossover platforms feature modular construction like elevated work platforms: strong, durable, corrosion-resistant frames and guardrails with anti-slip, non-bounce, self-draining treads for stairs and walkway decks. They can even be used on the rooftop for maintenance workers performing inspections, maintenance, and repairs to the roof or building services equipment (e.g., climate control and exhaust systems).

How can we help you?

Safety in the hotel/hospitality and recreation/entertainment industries requires attention to accessibility and the use of effective fall-protection equipment. Businesses that choose to create safe environments for their guests and employees will not only comply with regulations but also foster a positive reputation.

If you are responsible for safety, accessibility, or events management, FlexDecks can help. Our comprehensive services include hazard assessments, design and consultation, engineering, manufacturing, installation, and follow-up inspections and maintenance. Contact us for an evaluation of your facility’s safety needs.