How to Assess the Hazards and Meet the Requirements for Your Elevated Work Platforms

A political platform means you stand for something to help your constituents.

A work-at-height platform means you stand on something to help you do your job.

The figurative-to-literal comparison does not end there. Constituents and companies care about safety, the economy, the environment in which they operate, and hometown sports.

companies, an elevated work platform on which they stand involves several steps: a hazard assessment; design and consultation; engineering, manufacturing, installation, and follow-up inspections and maintenance.

Politicians: you’re on your own.

Take measure with a hazard assessment.

Although modular work platforms can be purchased “off the shelf,” the first step should be a thorough hazard assessment to identify the tasks to perform and associated risks.

- Where will the platform be situated?

- What are the working heights?

- What are the load capacities needed?

- How large does the working surface need to be?

- Will the platform be outside on uneven terrain or in extreme weather conditions?

- Are there special needs or modifications, such as adjustable height or services (e.g., electricity, water, shop air)?

A hazard assessment also considers applicable safety regulations and industry standards to minimize liability. For example, OSHA Part 1910, Subpart D, Title 29—amended in April 2024—provides a comprehensive definition of terms for walking/working surfaces. Not all regulations will necessarily apply to your work platform, but you must know your compliance guidelines.

Talk it out with design and consultation.

After the hazards and the applicable regulations are identified, the design and consultation phase commences to develop a working concept that meets operational needs and prioritizes safety. This cooperative effort refines the hazard assessment concerning specific needs and challenges.

For example, what are the platform dimensions? Access points? Guardrail configurations? What are the best construction materials? To illustrate, both galvanized steel and aluminum are strong, durable, and corrosion-resistant; however, aluminum is better in corrosive working environments, such as petrochemical plants, wastewater treatment facilities, metal foundries, mining operations, and marine environments.

Figure it out with engineering.

Once the design is determined, engineering helps turn concepts into reality to ensure that work platforms meet safety standards and functional needs. “Off-the-shelf” work platform solutions are one thing. The more sophisticated the design, the more advanced the modeling and simulation techniques needed to gauge load distributions, stress concentrations, and dynamic responses under various scenarios.

OSHA’s key standards for manufacturing the work platform.

The manufacturing process ensures that the work platform is built to the standards brought through the hazard assessment, design and consultation, and engineering phases.

OSHA 1910.29(b)(1) & 1910.29(b)(3) – Guardrails

Platforms four (4) feet or higher must have guardrails on all sides at least 42 inches tall (plus or minus 3 inches) and withstand a force of at least 200 pounds (890 N) applied downward or outward within two (2) inches of the top edge at any point along the top rail.

OSHA 1910.23(e)(1) – Stairs and Ladder Stands

Stairs should have uniform step intervals of no more than 9-1/2 inches, a tread depth of at least 9-1/2 inches, and a width of at least 22 inches.

The design and engineering phases should specify an anti-slip tread for steps and platform floors.

OSHA 1910.29(b)(13) – Safety Gates

When guardrail systems are used at access points, the guardrail system should have a self-closing gate to prevent an employee from walking or falling from height.

Installation puts it all together.

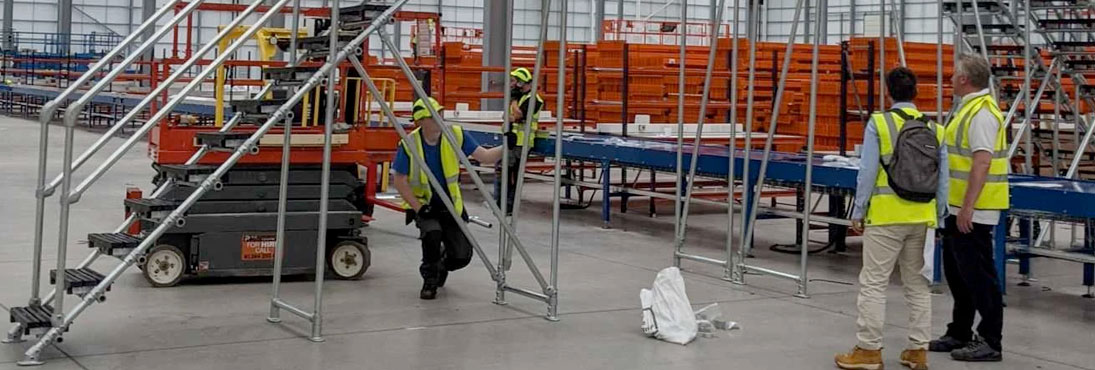

Installing a work platform reaches back to the hazard assessment and other phases to understand the situation and any challenges of where the platform will be used. It may take full turnkey assembly by qualified technicians. However, a pipe-fitted modular work platform installs easily on-site without welding or drilling.

Follow-up with inspections and maintenance.

Regular inspections and maintenance will help ensure the work platform’s structural integrity, functionality, and continued worker safety after it is installed and presumably in heavy use. Are there signs of wear, corrosion, or other concerns that should be addressed?

A pipe-fitted modular work platform has another advantage. If the work requirements or conditions change, the platform can be reconfigured.

How can we help you?

If you are responsible for work-at-height fall protection in your facility, FlexDecks can help. As noted, our services include a hazard assessment, design and consultation, engineering, manufacturing, installation, and follow-up inspections and maintenance. Contact us for an evaluation of your facility’s safety needs.