Enhancing Safety and Productivity for an Industrial Repair Facility

Home maintenance and repairs. They get put on a list. Some of them even get done, though the job may be stretched out if friends, relatives, or neighbors help. If it’s serious, someone calls a professional.

Industrial maintenance and repairs. No such luxury. They are critical to operations, and efficiency is paramount. Professionals are already on the payroll.

A major chemical processing and fluid engineering company with 180 manufacturing plants worldwide provides pumping, agitation, mixing, separation, purification, crystallization, and polymerization technologies for a wide range of fluids. Rotors and turbines are regularly maintained and repaired at a service center in the U.S. This requires frequent work at height and concomitant fall protection for the workers.

The company articulated to FlexDecks what they needed and wanted, which put in motion a series of problem-solving steps that surprised the customer at how much could be accomplished at such a modest cost.

Step #1 – Hazard Assessment

In October 2022, FlexDecks visited the service center, which has 277,000 sq. ft. in the repair facility and 90,000 sq. ft. of office space. The hazard assessment included collaboration with personnel to identify and understand the requirements, challenges, and objectives. Considerations included the layout and dimensions of the work areas, types of equipment serviced, and safety regulations. Factors such as mobility requirements, weight capacity, and ergonomic design were also evaluated.

Step #2 – The Hierarchy of Fall Protection

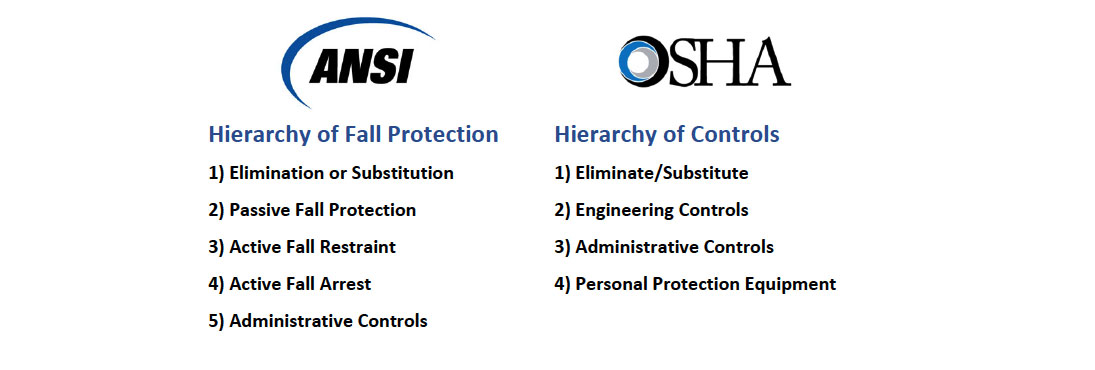

Photos, measurements, and field notes were reviewed at FlexDecks. It was determined that the best option to protect the workers would be to follow the first rule of the Occupational Safety & Health Administration’s “Hierarchy of Controls” for fall protection and safety concerns: eliminate the hazard.

FlexDecks recommended that the center should remove the risk to workers by reorienting the repair process from the ground instead of performing it over the top. This approach proved to be a no-cost solution for all but one of the tasks.

Step #3 – Engineering the Solution

In February 2023, the service center reported that work at height access and fall protection would be needed for workers to attach shackles to heavy discs ranging in diameter from 70 to 120 inches. This would enable the discs to be lifted by crane and placed on lathes for the manufacturing process.

Based on the customer’s conceptual drawings and knowledge from the hazard assessment, FlexDecks submitted a proposal for an engineered work platform by the end of February and followed up with another site visit in early March to confirm measurements. The proposal was accepted later in March.

Step #4 – Putting it Together

The two-part solution first involved having the center reorganize the discs by size, from smallest to largest. The second part was to manufacture a customized mobile access platform to handle all but the three largest discs.

Supported by pipe-fitted tubular rails, an anti-slip platform features a 10-ft. long by a 3-ft. wide deck with guardrails, toe boards, a self-closing safety gate, toe boards, and a weighted base to provide stability at the required clearance height to straddle the small and medium-size discs. Heavy-duty locking casters provide a work platform with station-to-station mobility so workers can move the platform to conduct each part of their work at height quickly and safely.

The delivered cost of the custom mobile work platform came in under the company’s budget.

How can we help you?

The journey from inquiry and hazard assessment to both a no-cost solution and a custom mobile access work platform enabled a service center for a major chemical processor to enhance productivity and worker safety.

If you are responsible for work-at-height fall protection in your facility, FlexDecks can help. Our services include consultation, design, engineering, installation, and more. Contact us for an evaluation of your facility’s safety needs.