How Modular Ramps “Cure” Wheelchair Access in Older Hospitals and Clinics

We may laugh in derision or gasp in horror about outmoded medical practices.

Going back to ancient times, leeches were used to extract blood from patients to combat many diseases—which may have contributed to the death of George Washington. Lobotomies were performed to treat mental illness. Even in relatively modern times, unnecessary tonsillectomies were carried out on children for recurrent throat infections.

Scientific advancements over the past decades have increased our understanding of how to treat medical conditions. The passage of the landmark Americans with Disabilities Act in 1990 was an outstanding achievement in our humanity and healthcare. Yet, that was not so long ago. Many existing hospitals and healthcare clinics were built before 1990 and must be upgraded to provide wheelchair access. Others constructed after 1990 may not have compliant access.

Fortunately, modular public access ramps enable these facilities to accommodate wheelchairs and comply with the ADA—and they require nothing in the way of blood, sweat, and tonsillectomies.

Obstacles to access.

- Hospitals and clinics that predate the ADA or are built in confined streetscapes may have structural limitations that hinder accessibility.

- People may be forced to use roundabout accessways or be hoisted up the steps. This can make them feel marginalized, cause unnecessary service delays, and jeopardize good health outcomes.

- Older facilities with ramps may not meet ADA requirements for slip-resistant surfaces, proper inclines, or the inclusion of handrails.

- Structural renovations to install compliant concrete ramps are time-consuming and costly.

- Local demands or emergencies may require a rapid expansion and adaptation of facilities.

- Hospitals frequently need to deploy modular triage rooms, surgical suites, and additional patient bedrooms, often requiring them to be raised above ground level.

The modular ramp solution.

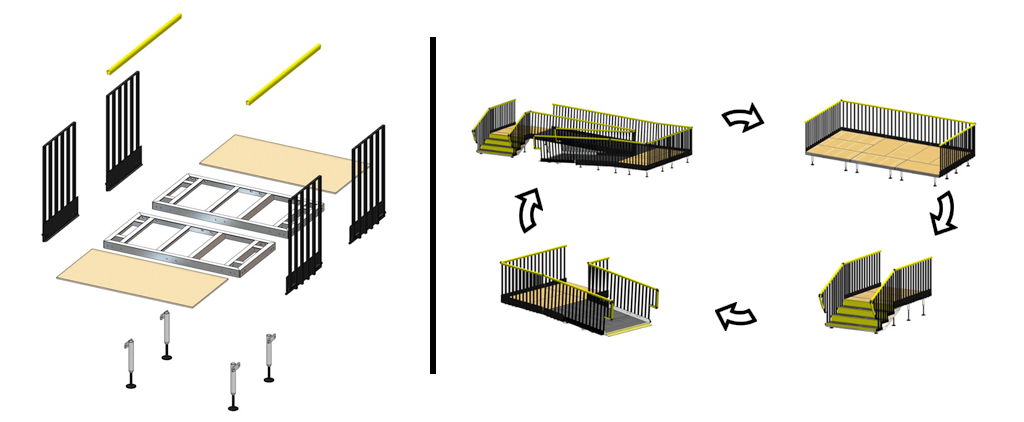

Modular wheelchair access ramps address these challenges. The flexible design enables ramps to integrate quickly and seamlessly into existing entrances and pathways or be incorporated into new structures. It eliminates the construction headaches and delays of renovations at a lower initial cost. Military-grade components contribute to an overall lower cost of ownership.

Third-party architectural and engineering services are unnecessary when selecting an appropriate and compliant ramp configuration. Installation is straightforward and does not require welding, skilled labor, or special tools. Ramps are typically up and running within one day and can be disassembled and reconfigured if the hospital’s or clinic’s needs change.

A prescription for prefabricated components.

Modular public access ramps built with securely connected, prefabricated components are load-tested to guarantee stability and engineered to prevent rattling or wobbling. They will maintain a premier look and feel under high-volume traffic. Primary components include:

- Corrosion-resistant aluminum alloy floor frames and powder-coated steel balustrades for strength and durability.

- Fiberglass mesh walking surface for superior slip resistance in all weather conditions. Its non-reflective surface avoids blinding sunshine and temperature extremes.

- Adjustable ramp legs compensate for uneven ground surfaces; enlarged feet or slabs can be used for soft ground.

- “Warm-to-touch” continuous PVC handrail tube that does not get hot or cold.

Meets or exceeds ADA standards.

Whether modular or permanent, any modern wheelchair access ramp will (or should) meet or exceed ADA and other standards, such as the International Building Code (IBC).

- The ramp must have a slope of 1:12 – 12 inches of ramp for every inch of rise.

- Minimum width of 36 inches between handrails – greater in some states.

- A rest platform for every 30 inches of vertical rise.

- Top and bottom landings at least 60 inches long.

- Protected edges at the walking surface so there is no risk of wheels or canes slipping from the edge

- All ramps over 6 inches tall must have continuous handrails on both sides.

How can we help you?

RightWay Pro is the newest entry in North America for modular ramp solutions. This premium offering delivers best-in-class slip resistance with fiberglass grating, military-grade durability, unique warm-to-the-touch handrails, and powder-coated aluminum guardrails for a high-quality presentation to your patients and families. Of course, ADA and building code compliance provide. They offer ADA-compliant, dignified, and comfortable access for improved patient outcomes to everyone.

If you are responsible for facilities management or ADA compliance for your healthcare organization, FlexDecks can help. Our comprehensive services include hazard assessments, design and consultation, engineering, manufacturing, installation, and follow-up inspections and maintenance.

Contact us for an evaluation of your facility’s safety and work platform needs.