Platforms Provide Stable Fall Protection in Sawmills

Fueled by abundant lumber, waterpower, and an unquenching demand for wood and wood products, sawmills were one of the earliest industries in colonial America. Circular saws, steam engines, and other technological advances have transformed the industry over the centuries, and innovation continues today with the employment of lasers and computer software.

However, the danger of working in a sawmill has been constant throughout history. The Occupational Safety and Health Administration (OSHA) considers sawmills one of the most dangerous occupations in the United States. In a recent one-year period, the agency conducted 72 inspections and issued 272 citations totaling nearly $1.5 million in fines.

While hazards at a sawmill vary greatly (e.g., noise, fire, particulate matter, power transmission, machine guarding), the need for fall protection manifests in several areas, from tarping loads on flatbed trailers to navigating slippery services, unstable scaffolds, inadequate ladders, and working at height to service large, highly mechanized equipment.

In and Out with vehicle access platforms.

For loading and unloading, tarping, and vehicle maintenance, a modular vehicle access platform provides stable fall protection. Constructed of strong, durable, corrosion-resistant aluminum or galvanized steel frames and OSHA-compliant railings, these platforms feature aluminum or glass-reinforced nylon treads for steps and decks that are anti-slip, non-bounce, and self-draining.

A flatbed trailer stand features heavy-duty casters with brakes to roll up to the trailer and lock it in place. Standard models are 5-ft. high and 53-ft. long to match typical flatbed decks; however, built-to-size configurations are available. It has a 4:1 safety factor and has a rated load of 900 lbs. for three workers. Each stair has an ultimate load of 1200 lbs. The entire platform has an ultimate load of 3600 lbs.

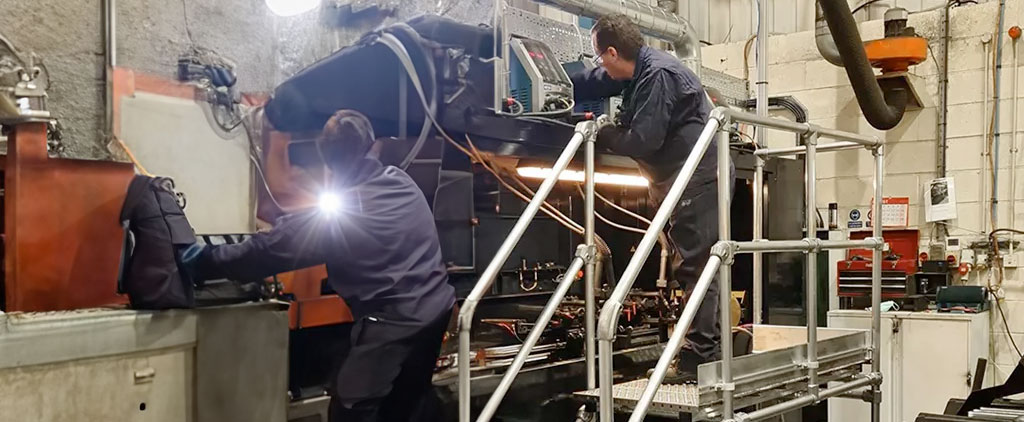

Up and down with equipment access platforms.

From floor level to perches above large machinery and equipment, sawmills have log debarkers, carriages, saws, edgers, planers, sorters, stackers, conveyors, and drying kilns that workers must access for production, inspections, cleaning, and maintenance.

OSHA 1910.265 specifies safety requirements for sawmill operations. Section C4 spells out regulations about walkways, docks, and platforms. They must be:

- Wide enough to provide adequate passage and working areas.

- Evenly floored and kept in good repair.

- All elevated walks—if four (4) feet or more from the floor level, must have a standard railing on all open sides except where there is an entrance. (If the height exceeds six (6) feet, it should also have toe boards to prevent material from rolling or falling off.)

- Elevated platforms used daily shall have stairways or fixed ladders that comply with OSHA 1910.21 (for safety and stability).

Modular work access platforms are essentially built to size to comply with OSHA and meet the facility’s production and maintenance requirements. As with vehicle access platforms, they are constructed of pipe-fitted aluminum or galvanized steel components for frames and railings, plus anti-slip treads for stairs and decks. They are easy to expand or reconfigure as needed.

Types of elevated platforms include:

Fixed Platforms – Designed for permanent installation and frequent use.

Mobile Platforms – Equipped with braking casters for station-to-station portability.

Adjustable-height Platforms – Engineered to allow workers access to different heights from one platform. Welded designs are in accordance with AWS D1.1 & D1.2 and inspected by our certified welding inspector.

Custom Work Platforms – Can be fitted with ramps, shelves, racks, toe boards, self-closing safety gates, shop services (e.g., air, water, electrical), and other features as required to perform work at heights safely and productively.

How can we help you?

Whether accessing vehicles or large equipment, elevated access platforms improve worker safety and morale, boost efficiency, and bring sawmill operations into regulatory compliance for critical areas of fall protection. If you are responsible for worker safety at your sawmill, FlexDecks can help. Our comprehensive services include hazard assessments, design and consultation, engineering, manufacturing, installation, and follow-up inspections and maintenance.

Contact us for an evaluation of your facility’s safety needs.